How Long Does It Take to Boil Chicken in Water

Sometimes the objective of boiling water isn't to get hot water. You might boil it to create steam, say, to turn a turbine and create power. A lot of heat might get wasted doing that boiling. But a new method for heating up water might change that.

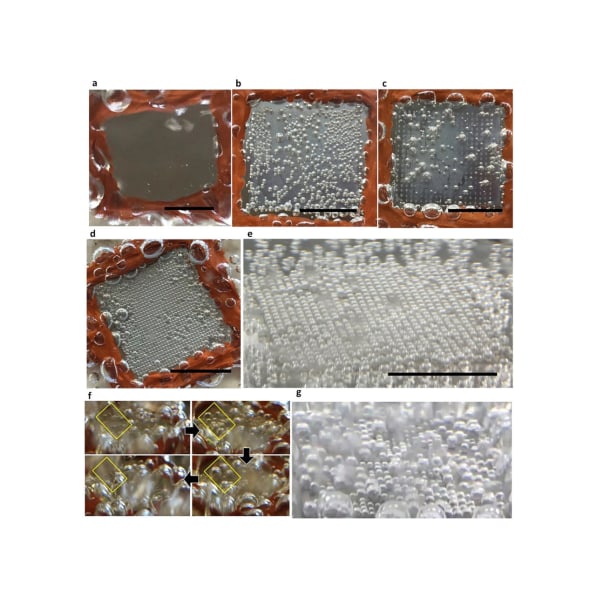

By tuning the creation and release of bubbles in boiling water, more steam is created, and the size of these steam bubbles can be precisely controlled, along with the rate of their release. This also lets you get the heat out of the water a lot faster, making it a much better cooling agent.

The new method, discovered at Oregon State University and published in Nature, uses nanomaterials to do the job. The surface of the boiling vessel is printed first with hydrophobic (water-repelling) polymer dots. Then a pattern of water-attracting (hydrophilic) nanomaterial is deposited. This pattern of attraction and repulsion allows the surface to be configured for the precise creation of bubbles in boiling water. The job of printing the nanoparticles is done by a standard inkjet printer.

When water reaches a boiling point, it doesn't necessarily turn to steam. It needs some kind of physical spot–a "nucleation site"–to form a bubble. This can be an imperfection or crevice in the surface of the container. That's why a clean, scratch-free jug of water heated in the microwave can seem to be below boiling point, but explode as soon as you move it. The water in there is super-heated beyond 212 degrees, but hasn't found any nucleation sites to let it turn into steam. When you disturb it, swirls in the water can be enough to release all that pent-up energy into steam. Another example is throwing salt into boiling pasta water. It suddenly roils because you just tossed a handful of nucleation sites in there.

By precisely controlling nucleation, the Oregon State team can choose how the water boils. The more bubbles, the more heat can escape, which is perfect if the water is a coolant. Anywhere that heat has to be quickly dissipated, this new method can help, from power stations, to high-power lasers, and some kinds of solar energy.

If your goal is to make as much steam as possible, perhaps in an turbine generator, then the nano-printed surface helps there, too, letting water turn to steam with a lower surface temperature, which in turn uses less energy. In tests, the new surface is three times better at turning water to steam than a bare stainless steel surface.

As you can see in these pictures, the technique is so precise it can be used to write letters with the bubbles of steam as they form. Creating a printing pun involving bubble jets and dot matrices will be left as an exercise for the reader.

The ease of treating materials, using standard, off-the-shelf printers, could lead to adoption of this new boiling method in large-scale electricity-generation plants, and also in small, heat-dissipating components inside electronic devices. The possibilities are as varied as the range of devices that use water for cooling, or steam for, well, for steaming things. And the best thing about this tech is that it works on top of other methods. Combined in a power station with Germany's ultra-efficient coal burners, for example, it could allow for a lot more electricity to be produced from the same amount of coal.

How Long Does It Take to Boil Chicken in Water

Source: https://www.fastcompany.com/3059625/science-invents-a-better-way-to-boil-water

0 Response to "How Long Does It Take to Boil Chicken in Water"

Post a Comment